Report 'Chain Approach as a Motor for Industrial Transformation: An Analysis of the Raw Materials Transition'

In the Netherlands, many parties are committed to an industry where sustainability and digitalisation are the leading principles. From sustainable construction to setting up chains for the production of quantum computers, and from cyber resilience to biobased plastics: there is no shortage of initiatives. The initiators are trying to switch to sustainable business models with a lot of positive energy, contributing to long-term and broad prosperity for the Netherlands. That is the good news. The less good news: despite all these beautiful initiatives, the transformation of the industry is not really taking off.

Small Steps

More is needed. What exactly? “One thing is clear: there is no such thing as a silver bullet,” emphasises Lotte de Groen, business developer at TNO Vector. “This is because many factors play a role, such as legislation, financing possibilities, chain dependencies, and geopolitical developments. It is complex. This requires a phased approach, with small steps, where we must constantly check whether such a step brings us further. But that is not how many parties in the industry envision the transformation. They are looking for an approach where they can implement the desired change in one go, preferably with precisely fitting policy and government funding. As long as there is no clarity and certainty, they keep waiting for each other, and nothing happens. A shame, because there are enough small things they can start with today. By experimenting, they can gain new insights and solutions that can help us all move forward.”

No Party Can Do This Alone

“Collaboration is an important condition,” emphasises Willem Manders, innovation orchestrator at TNO Vector. “No party can shape an industrial transformation alone. This requires cooperation between different parties that implement changes in mutual coordination. For example, the supplier of sustainable raw materials cannot proceed if there are insufficient buyers. This is currently happening with plastic recyclers. To solve such problems, new value chains are needed where chain collaboration is central. In places where this happens, you see that chain partners achieve great things in a short time.”

Completely Different Worlds

But how do you launch such a new value chain, where all participants are committed to an industrial transformation and have the same vision? “That is a good question because in new chain collaboration initiatives that focus on sustainability, you often see that parties from different worlds have to work together,” says Manders. “I regularly experience this up close, sitting at the table with people who have never met before. As TNO, we facilitate them getting to know each other first because without openness and trust, you get nowhere.”

Coalition of the Willing

Not immediately getting down to business, but first paying attention to the human aspect and everyone’s interest in the change. That is where it starts. The first meetings are therefore about sharing wishes and expectations. It helps if the different participants each organize a meeting. When they visit each other, a trust basis often naturally forms, which can be built upon. “It helps to start with a coalition of the willing,” says De Groen. “Then there are parties at the table who already see the benefits of chain collaboration. When exploring possibilities, they are more willing to look beyond their own business model and focus on the common interest.”

Bridge Builder

Are important parties missing at the start meeting? According to De Groen, this does not have to be a problem: “It often turns out to be possible to set up part of the chain with the present participants and set up experiments that help elevate such collaboration to a higher level in a short time.”

“And as TNO, we act as a kind of bridge builder,” adds Manders. “We look at the business models of the involved parties and see if we can come up with business models for the new chain that everyone can agree on. Often, uncertainties come to light in this exploratory phase that can only be solved by other parties. The government, for example. As TNO, we take that on.”

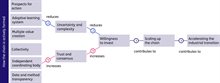

Six Principles

Besides the fact that industrial transformations are already very complex, it is not certain in advance who the winners and losers will be. This creates uncertainty. If there is no good thought about how parties can come to a fair distribution, disagreements about the approach can quickly arise. A transformation is only possible if it succeeds in reducing complexity and uncertainty and ensuring that disagreements between different parties decrease. Based on this insight, TNO Vector has come up with six principles for a successful chain approach:

- Provide action perspective

- Form an adaptive learning system

- Create multiple values

- Start from commonality

- Build on an independent director

- Be transparent

Gaining Practical Experience

So much for the theory. Meanwhile, De Groen, Manders, and other specialists from TNO Vector are already working on various chain collaboration projects such as the Growth Fund Program BioBased Circular. “All this helps us to investigate in practice whether an organized chain approach is the best strategy to achieve successful industrial transformations,” says De Groen. “Our plan is to help hands-on with the chain approach in multiple sectors. Additionally, we want to create a community of people and parties involved in transitions and chain development and scaling. Because we are also looking for best practices in this area, and we are convinced that we can still learn a lot from each other.”

“We are very much looking forward to experimenting, learning, and advancing transitions in the projects we are already working on this year,” concludes De Groen. “And are you touched by this story? Then please contact us. Together we can move forward!”

What works well in chain collaboration and what does not? To learn from each other, TNO organised a meeting for peers involved in chain development and scaling in October last year. Such an event will also take place this year. Want to stay informed about developments in chain collaboration and receive a message once a date for the next meeting is set? Then send an email to Lotte.degroen@tno.nl.

Achieving Active Chain Formation: Six Principles